COMPANY

WHO WE ARE?

We are not an assembly plant!

We are a company based in Queretaro, dedicated to the making of steel and the development and production of metallic products. We also offer assessment and business planning to conform to our clients’ needs.

DIRECTORY

Technical Director

Marketing Manager

Ing. Pedro González Hernández

e-mail: p.gonzalez@cosi.mx

Ing. Benito González Hernández

e-mail: benito@cosi.mx

MISION

To be a leading business on the market, offering the best attention, service, quality and price, continuously improving our processes and the development of our qualified technical staff.

VISION

To become a point of reference for others in the business sector; with leadership in our products and specialized services, surpassing our clients’ expectations.

VALUES

Honesty / Accountability / Commitment / Team work / Excelent service / Loyalty

COMPANY VALUES

Attention on quality in COSI, we promise to continuously improve our processes to satisfy our clients’ needs, offering quality, service and quick, trustworthy response rates. The most important and valuable part of our company “the people that work in it”.

For this reason, our staff has continuous training through courses and manuals to assure the best personal quality of each of our members.

Improved staff quality = satisfied customer

Recommendations to Novel entrepreneurs

AUTOMOTIVE LINE

PRODUCTS / AUTOMOTIVE INDUSTRY

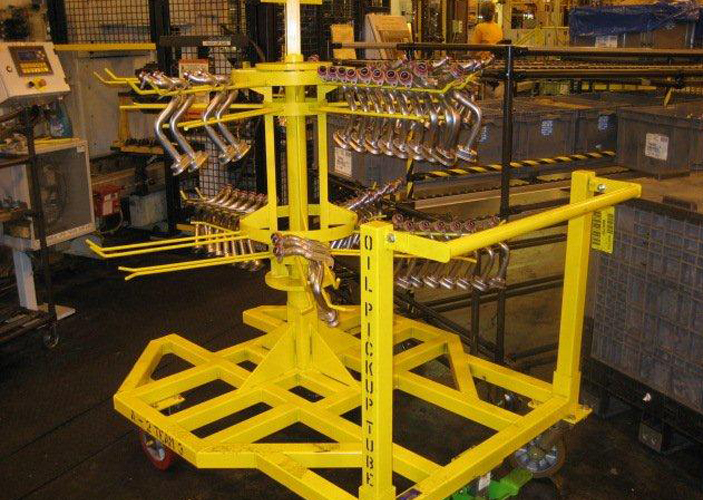

We develop the necessary equipment for material handling

dynamic racks, minomis, dollies, transfer trucks, conveyors dynamic.

Our manufacturing processes are governed by the Management System Quality

ensuring effective and efficient product development.

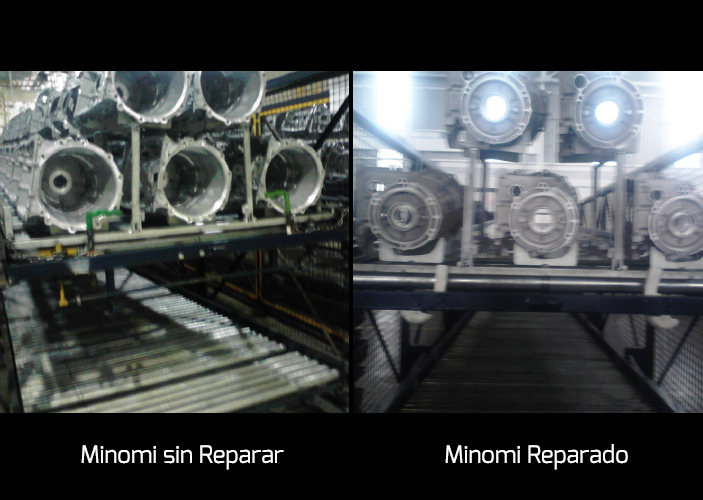

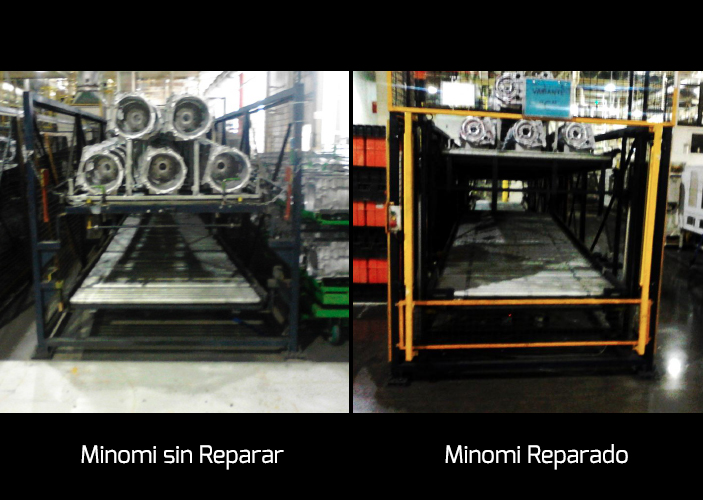

Dynamic Rehabilitation Racks

We maintain and extend the life of dynamic racks.

Manufacturing Platforms

Develop materials handling projects.

Manufacturing and Engineering for metal decking.

Design according to the characteristics of the material and container.

TANKS

Tanks

Development, manufacture square, elliptical, round tanks, pedestal floor level and higher.

Storage tanks used in the industry.

For storage of raw and finished products for all fields of industry materials.

Elevated water tanks

Elevated water tanks are made of commercial steel. Provide water pressure allowing the water to travel the piping system at high speed and time to reach households to force several miles away.

MANUFACTURE OF METALLIC PRODUCTS

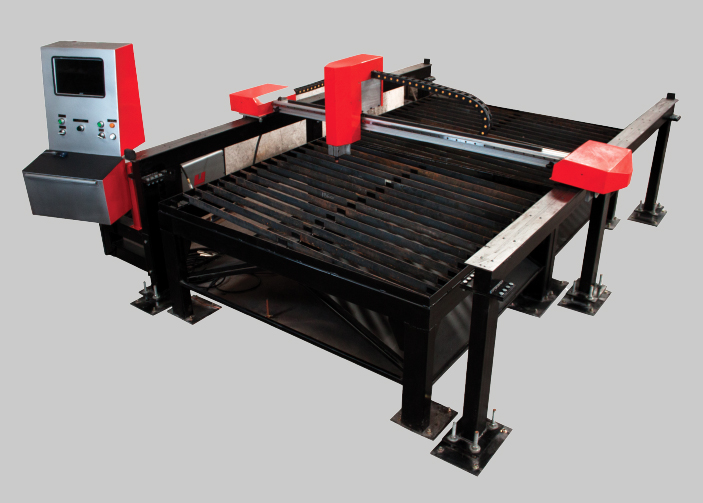

Cut with Tables of C.N.C. for Plasma cutting

Cut with Tables of C.N.C. for Plasma cutting

Cut with Tables of C.N.C. for Plasma cutting 20' 6'x capacity up to 1" thick, effective cutting.

We have technical department for advice, development and cut, straight cut, cut any figure in materials: commercial steel, stainless steel, aluminum.

Quick - 25000 mm / min (1000 "/ min) V max.

Accurate - Servos Stepping motor on axis "X", "Y"

Friendly - Integrated Software Design and control.

Ohmic sensor and advanced control height.

SERVICES

SPECIALIZED CUTTING PROCESSES

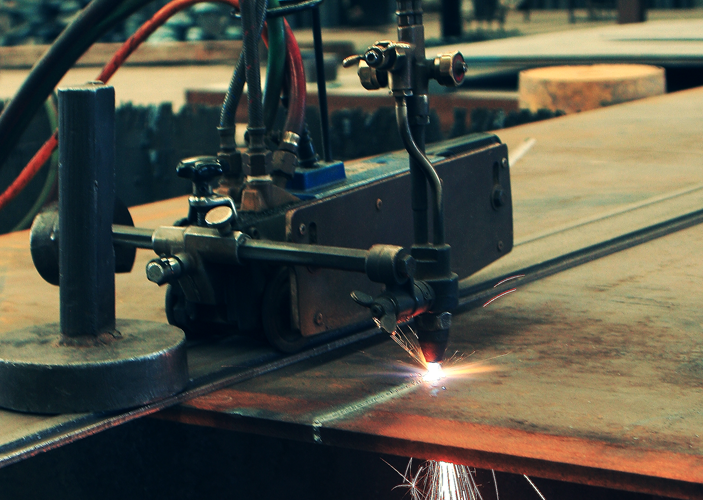

Machining

Operation performed with mechanical shear to leave as a laminate or profile only straight cuts.

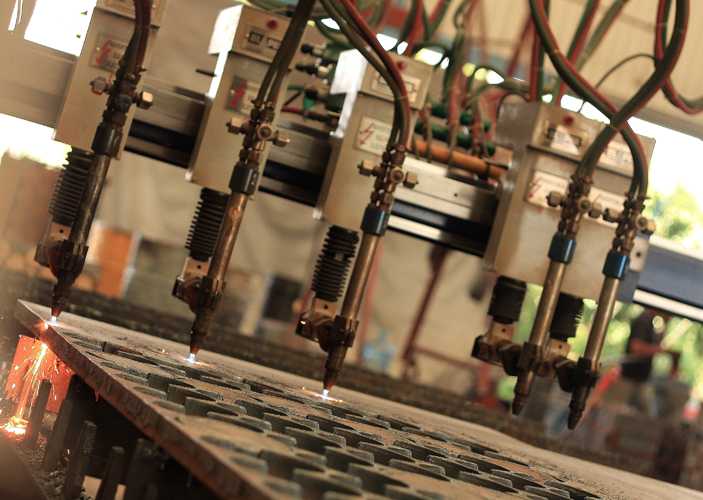

Automated

Mechanized operation on CNC plasma pantograph for straight cuts and figures laminates or rods of ¾.

MAQUILA FOLD

Operation of a mechanical folding press to make angular forms out of any kind of sheet metal.

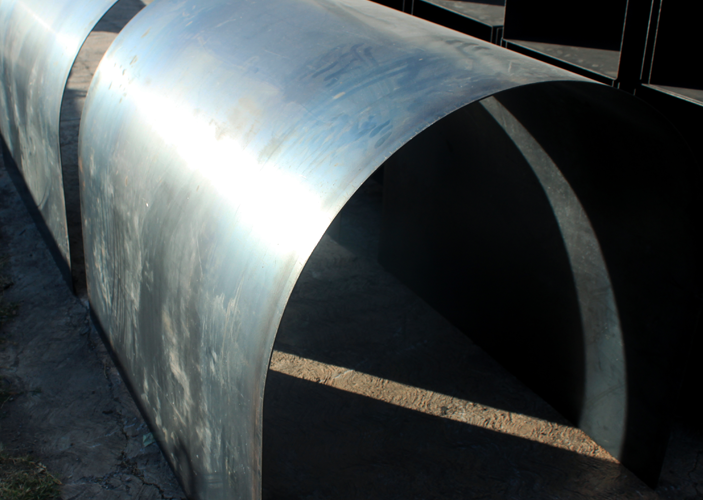

MAQUILA ROLADO

Operation of rolling machinery to give cylindrical or curved forms out of sheet material or profiles.

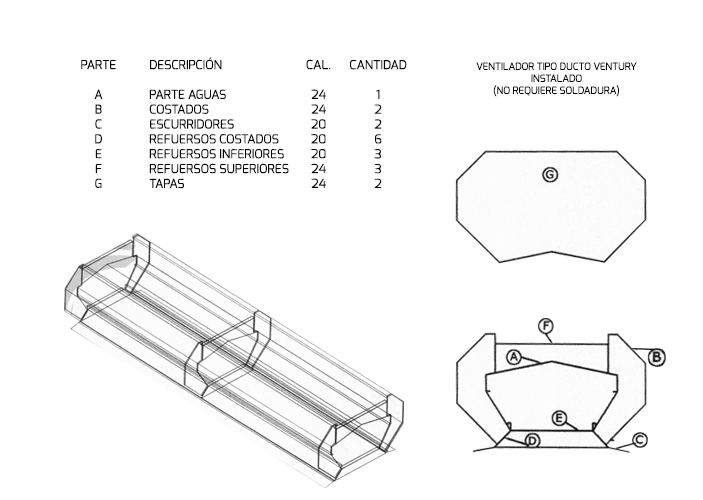

CURVED AND TORIESFERICAS CAPS

Specialists in designing and manufacturing all kinds of curved and toriesfericas caps and stainless steel business for the processing industry and steel transport tankers.

PAILERIA

Professional specialty welding for the construction of metal structures, suitable for storage, transportation of solid , liquid and gas deposits.

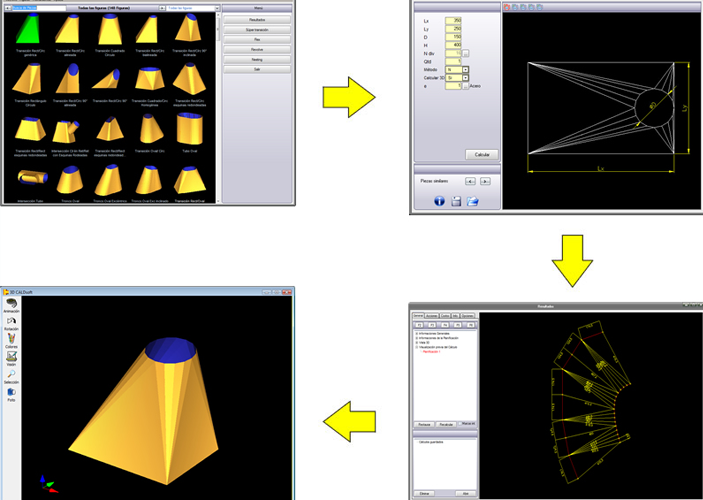

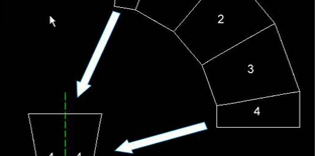

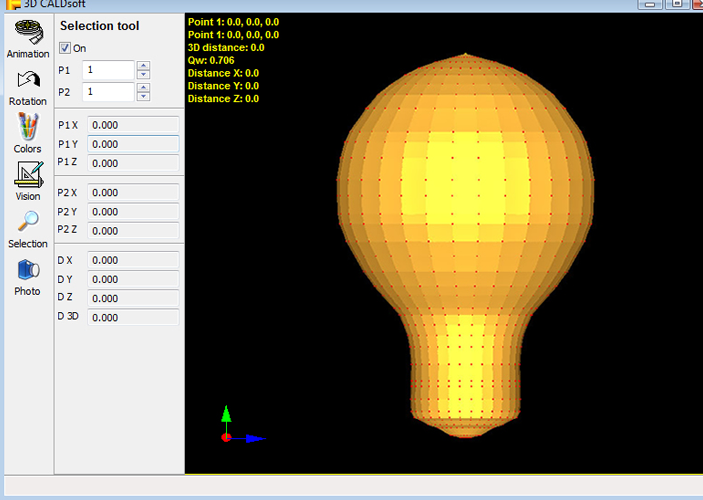

For automatic calculation of schedules used parts CALDsoft7 Planning Software, which increase productivity, decrease costs by taking advantage of the raw material and optimization of schedules .

It is an intelligent method which enables the automatic and optimized choice for the number of marks (divisions) depending on the type of process allows "mirror " the piece so that the marks or fall inside or outside , facilitating adaptation manufacturing process.

All pieces can be viewed in 3D allowing verification of installation dimensions , with planned CALDsoft7 any transition or intersection between two pieces .

The use of sheet module (Nesting) allows distribution of all planning computed in one or more patterns , giving an accurate picture of the layout .

BRAZING

The different types of soldering that we use in our assembly process is:

Covered Electrodes

The process of arc brazing with electrodes, an electric arc is formed when the electrode contacts the workpiece to be welded, then the electrode is consumed as the weld bead is formed as protection against contamination of atmospheric air is by gas and slag from the merger of its coating atmosphere.

Brazing with coated electrodes used in the manufacture, installation and maintenance of various equipment and structures. The process is primarily used as a manual operation.

Advantages:

Availability and variety of supplies for various applications.

Large operational flexibility.

Special with Wire

It is a semi-automated process or using a continuous feed of wire as an electrode and a mixture of inert gas or inert semi-brazing to protect against contamination.

This type of brazing is suitable for production brazing.

Botted

It is a resistance welding method, useful in metal sheets applicable normally between 0.5 and 3 mm in thickness, which is achieved by heating a small area by circulating an electrical current.

The principle of operation of this process involves passing an electric current through intensive metals to be joined. Taking advantage of this energy and with a little pressure the union is achieved. The power passes through a transformer in which the tension is reduced and the intensity rises considerably to increase the temperature.

QUALITY

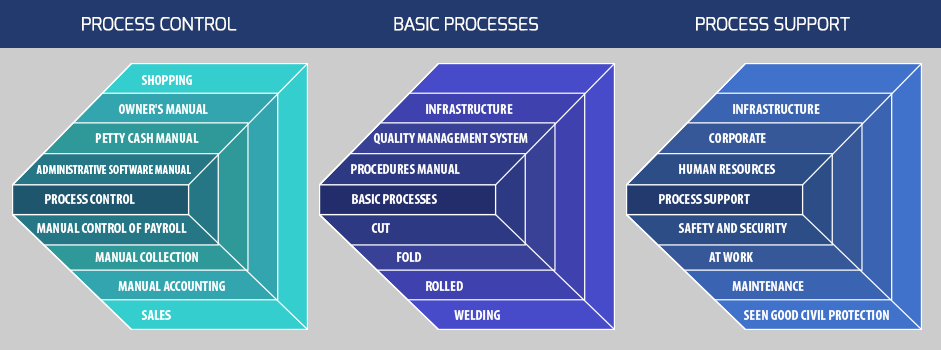

Management System Quality at COSI

specifies the necessary elements to

a) Demonstrate our capacity to provide products that meet and satisfy the needs and requirements of our clients and the applicable recognized standards.

b) To increase our clients’ satisfaction through the application of continuous improvement processes and to assure our clients’ specifications are met as well as the pertinent standards.

The system of quality management of COSI reaches all the processes of reception and storage of raw materials, processes of cutting, folding, rolling and soldering; storing of unfinished and finished products; product delivery according to the clients’ needs.

The Management System Quality at COSI is in line with the elements establised in the ISO 9001 : 2000 norms, excluding the following articles:

- 7.5.2 validation of the production processes and services provided, due to the fact that products processes by COSI verified internally.

This exclusion does not affect the ability and responsibility to COSI to provide a product that meets customer requirements and applicable regulations.

Tracking Procedures

With the objective of identifying the state of the product with regards to its required specifications, at COSI, we have implemented the use of tags that indicate the product’s progress during the fabrication process and the final production stage, as a form of product identification.

CONTACT

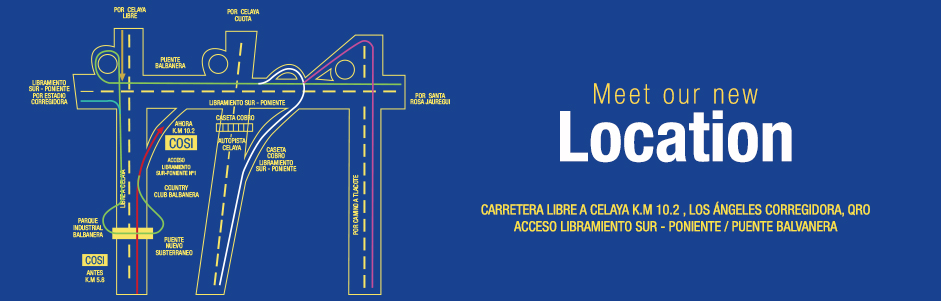

Google Map

CONTACT US

Carretera Libre a Celaya K.m. 10.2, Los Ángeles, Corregidora, Querétaro. Acceso Libramiento Sur – Poniente / Puente Balvanera.

Metallic Products

Phones. 01 (442) 225 04 83, 257 02 07 y 225 37 19